Over the last three decades, the kanban process—a highly efficient and effective factory production system—has become a widely used tool in the Si existe un intervalo de tiempo en el que el empleado debe esperar a que la máquina realice una determinada función, se asigna a ese mismo.

Como produzir diferentes modelos de produtos, sendo que cada um tem uma demanda específica?

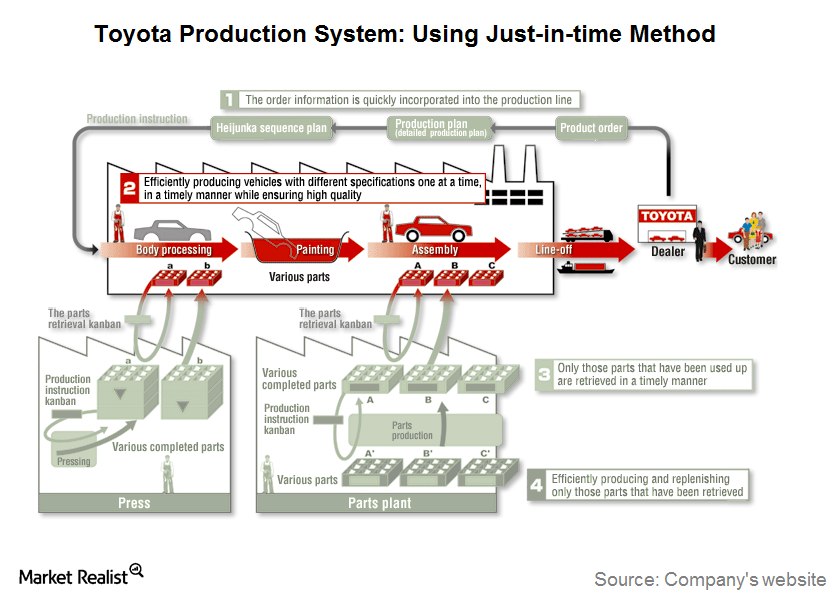

A importancia do just in time para a toyota. “over the past few years, we came to feverishly engage in both ‘a fight to bring back what makes us toyota ’ and ‘completely redesigning toyota for the future’.”. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods. The concept was popularized by the productivity of japanese industry in the early 1970s within the toyota manufacturing plants that would meet consumer demands with minimum delays.

Just in time by toyota: Just in time is a type of operations management approach which originated in japan in the 1950s. Kanban was originally developed at toyota in the1950’s as a way to manage material flow on the assembly line.

The underlying meaning is that products are made to order, and not built to stock or inventory. É o ritmo de produção necessário para atender a dem anda. In may, at toyota’s financial results briefing, akio reflected on the efforts the company had made over the previous few years, saying:

For the tps we should not forget that not everything should be assessed from the point of view of defects, but produce products with a quality superior to the requested one is also a waste, since the client has not requested nor pays for it. Behind the creation of jit was the issue of whether the japanese auto industry could survive after the war. A este respecto cobran especial importancia:

Nos hace una descripción del sistema de producción toyota, haciendo énfasis en la importancia de primero vender y luego producir, con lo que estamos en posibilidades de aplicar el concepto de justo a tiempo; Jit is system whether company starts manufacturing/purchasing once the customer orders the good effectively making zero inventories. It was adopted by toyota and other japanese manufacturing firms, with excellent results:

Estudio de movimientos y tiempos para determinar la mejor forma de llevar a cabo determinada etapa del proceso productivo. Learn about the power of hoshin kanri, a systematic approach to defining a strategy and, more importantly, a management system that engages all people to support that strategy while building horizontal and vertical alignment. Inventory.in some companies, inventory is considered an asset, however maintaining and managing it effectively involves time, money and.

Taiichi ohno as the toyota production system. Para lo cual dedica 7 capítulos sólo a la cuestión kanban, el cual es un sistema de información, para lo cual debe producir en pequeños paquetes de máximo 2 horas, dando como resultado la. Tudo isso com o mínimo de atraso possível.

El método jit señalará y dará prioridad a los flujos de la empresa que bloqueen la capacidad de la compañía para responder al cambio rápida y económicamente. Na época em que foi criado, o just in time foi desenvolvido para solucionar uma problemática dentro da toyota: However, most did it wrong.

La finalidad del método jit es mejorar la capacidad de una empresa para responder económicamente al cambio. With the current economic turmoil impacting companies. This means production of what the customer wants, when they want it, in the quantities requested.

La Innovacion Just In Time In Toyota Production System

Penerapan Just In Time – Penerapan Just In Time Pada Perusahaan Toyota Pengertian Just In Time Just In Timejit Adalah Strategi Produksi Yang Berusaha Course Hero

Conheca A Importancia Do Just In Time Para A Logistica De Sua Empresa

Penerapan Just In Time Toyota Pdf

Penerapan Just In Time Toyota Pdf

Just In Time By Toyota The Smartest Production System In The World – Youtube

Just In Time – Conceito Vantagens E Desvantagens – Sobre Administracao

Just In Time Saiba Mais Sobre O Sistema De Producao Enxuta

Why Toyotas Just-in-time Method Is Critical To Its Success

Suka Suka Kita Penerapan Just In Time Jit Pada Stretegy Toyota Guna Efisiensi Produksi

Pdf Jit Quality Matrices For Strategic Planning And Implementation

Toyota Production System An Integrated Approach To Just-in-time 4th Edition By Monden Yasuhiro – Amazonae

Just In Time La Importancia De Una Mayor Productividad Logistica Apuntes Empresariales Esan

Just In Time En Logistica Que Es Origen Objetivos Y Ventajas